News

How are Paper Tubes and Cans Used for Tape and Label Manufacturers?

Answer: Tape and label manufacturers rely on sturdy, reliable cores and packaging to ensure their products are efficiently produced, stored, and shipped.

Paper Tubes and Sales Manufacturing (PTS), a leading independent manufacturer of paper tubes, cores, and composite cans, offers tailored solutions that significantly enhance operational efficiency for these industries. With over 35 years of experience and a 60,000-square-foot facility, PTS provides high-quality,eco-friendly products that meet the unique needs of tape and label manufacturers. Here’s how PTS’s composite cans and paper tubes deliver substantial benefits, based on insights from their offerings at pts-mfg.com.

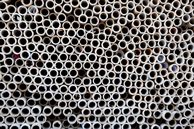

Precision and Durability for Tape and Label Cores

PTS specializes in manufacturing tape and label cores, offering 17 stock sizes for immediate shipment and custom options up to 30 inches in inner diameter. These cores, made from 100% recycled paperboard, are designed to be sturdier than standard paper towel cores, providing the strength needed to support heavy rolls of tape or labels during winding, packaging, and shipping. The ability to customize diameter, wall thickness, and length ensures cores are tailored to specific equipment and product requirements, reducing downtime and ensuring seamless integration into production lines. For example, PTS’s cores can be cut to precise lengths, with non-standard sizes available for second-day shipment, enabling manufacturers to maintain tight production schedules.

Cost-Effectiveness and Efficiency

Progressive die stamping reduces material waste and labor costs, making it a cost-effective solution for high-volume production. PTS’s automated manufacturing processes and in-house engineering expertise further optimize efficiency, allowing tape and label manufacturers to lower per-unit costs. The company’s ability to produce high volumes—supported by five winding lines and 12 re-trimmers—ensures rapid turnaround times, often within 2–3 days for stock products and two weeks for custom orders. This scalability minimizes supply chain delays, enabling manufacturers to meet market demands efficiently. Additionally, PTS’s competitive pricing and focus on customer-oriented service make their products an economical choice without compromising quality.

Sustainability with Eco-Friendly Materials

Environmental responsibility is a key advantage of PTS’s products. All paper tubes and composite cans are made from 100% recycled paperboard, aligning with thegrowing demand for sustainable packaging solutions. Metal closures, such as aluminum ends with over 75% recycled content, further enhance eco-friendliness. PTS also recycles manufacturing scrap back to paper mills, reducing waste. For tape and label manufacturers aiming to meet sustainability goals or appeal to eco-conscious customers, PTS’s “green” products provide a marketable advantage while maintaining durability and performance.

Customization for Branding and Functionality

PTS offers extensive customization options, including full-color printing and labeling, allowing manufacturers to enhance brand visibility on cores and composite cans. For instance, custom-printed paperboard shipping tubes can display logos or designs, adding professionalism to packaged rolls. Composite cans, used for retail or wholesale packaging, feature options like full convolute retail labels, foil linings, and various closures (e.g., tamper-evident tops, metal friction plugs) to ensure product protection and consumer convenience. These customizations not only improve aesthetics but also ensure compatibility with specific tape or label products, such as those requiring moisture-resistant linings for adhesives.

Versatility for Diverse Applications

PTS’s composite cans and paper tubes support a range of applications beyond core winding. Composite cans, available in diameters up to 6 inches, are ideal for packaging specialty tape products or labels for retail, with features like foil or poly linings to protect against environmental factors. Paperboard shipping tubes, equipped with metal or plastic end plugs, provide secure transport for rolled products, preventing damage during shipping. This versatility allows tape and label manufacturers to streamline packaging processes, reducing the need for multiple suppliers.

Reliable Service and Nationwide Distribution

As a family-owned business since 1973, PTS emphasizes personalized customer service. Their in-house engineering team collaborates with clients to design custom solutions, while their fleet of trucks ensures prompt nationwide delivery. This reliability is critical for tape and label manufacturers who need consistent supply chains to avoid production bottlenecks. PTS’s commitment to quality, backed by state-of-the-art equipment and a low defect rate, ensures manufacturers receive dependable products tailored to their needs.

If you’re looking for “GREEN,” look no further than PTS! After all, green is the color of PTS.