News

How Composite Cans, Paperboard Cores, and Tubes Are Used in the Construction Industry

The construction industry relies on innovative, sustainable materials to streamline operations and reduce environmental impact. Paper Tubes and Sales Manufacturing (PTS), based in Dallas, Texas, has been a trusted supplier for over 35 years, producing composite cans, paperboard cores, and tubes from 100% recycled materials. Operating from a 60,000-square-foot facility with nationwide distribution, PTS delivers customized, eco-friendly solutions that meet the construction industry’s needs for durability, cost-efficiency, and sustainability. Below, we explore how these products are utilized in construction applications.

Composite Cans for Material Storage and Protection

PTS’s composite cans, featuring poly-foil linings and heat-sealed metal or plastic tops, are used in construction for storing and transporting sensitive materials like adhesives, sealants, and chemical compounds. These cans, with skived bodies for enhanced column strength, protect contents from moisture, oxygen, and physical damage, making them ideal for on-site storage of caulks or coatings. Customizable with tamper-evident or child-resistant closures, PTS’s composite cans ensure safe handling of hazardous substances, while vibrant printed labels enhance product identification on busy construction sites.Paperboard Cores for Concrete Formwork

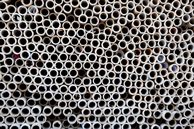

Paperboard cores from PTS, available up to 30 inches in diameter, are widely used as formwork for casting concrete columns and structural elements. These high-strength cores, made from 100% recycled kraft paper, provide a cost-effective, lightweight alternative to metal or plastic molds. Known as Sonotubes® in some applications, they support concrete pouring for columns, footings, and bridge deck formwork, offering excellent compression resistance. PTS’s custom engineering ensures precise tolerances and wax coatings for moisture resistance, enabling reliable performance in demanding construction environments.Paperboard Tubes for Shipping and Structural Applications

PTS’s paperboard tubes, including blueprint shipping tubes, are essential for transporting architectural plans, blueprints, and posters to construction sites without damage. Available with metal or plastic end caps (75% recycled metal), these tubes prevent bending or creasing during transit. Additionally, large-diameter paperboard tubes are explored in innovative structural applications, such as lightweight beams or arches in sustainable construction projects. PTS’s ability to customize sizes, add printing, or apply wax coatings enhances their utility for both practical and experimental construction uses.Benefits of PTS’s Solutions

PTS’s commitment to sustainability, using 100% recycled paperboard and refurbished pallets, aligns with the construction industry’s push for green building practices. Their state-of-the-art equipment and five winding lines enable rapid production—stock items ship in 2–3 days, custom orders within two weeks. Nationwide delivery via PTS’s own fleet ensures timely supply to job sites. By offering durable, customizable, and eco-friendly solutions, PTS supports construction firms in reducing costs and environmental impact. Call at 800-422-5108 or use our contact form.If you’re looking for “GREEN,” look no further than PTS! After all, green is the color of PTS.